It is a method of cold working in which compressive stresses are induced in the exposed surface layers of metallic parts by the impingement of a stream of shots directed at a metal surface at high velocity under controlled conditions.

Shot Peening when applied on following components increases its service life

Pins – 400-1900%.

Shafts – 700 %

Helical springs – 3500 %

Gears – 30 %

Valves – 700 %

Component: Aircraft propeller blade on Face and Camber

Advantages: Stress corrosion resistance, resistance to fatigue failure.

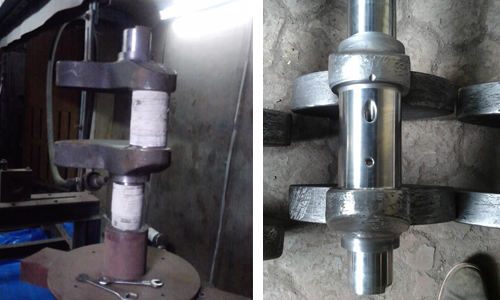

Component: Compressor crank Shaft radii

Advantages: Induce compressive stress to improve fatigue failure.

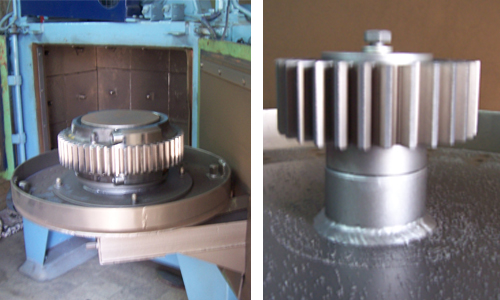

Component: Crankshaft gear, Pinions

Advantage: Resistance to fatigue failure, stress corrosion resistance, lubrication

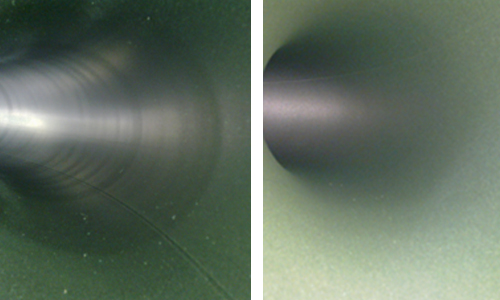

Components: PE granules transportation pipes

Advantages: Increase in flow rate, prevention of Angel hair formation, prevention of classifier choking,

Components: Collars

Advantages: Anti galling, stress corrosion resistance, resistance to fatigue failure.

Component: Centre shaft of Roll assy (5mtrs long)

Advantages: Resistance to fatigue failure